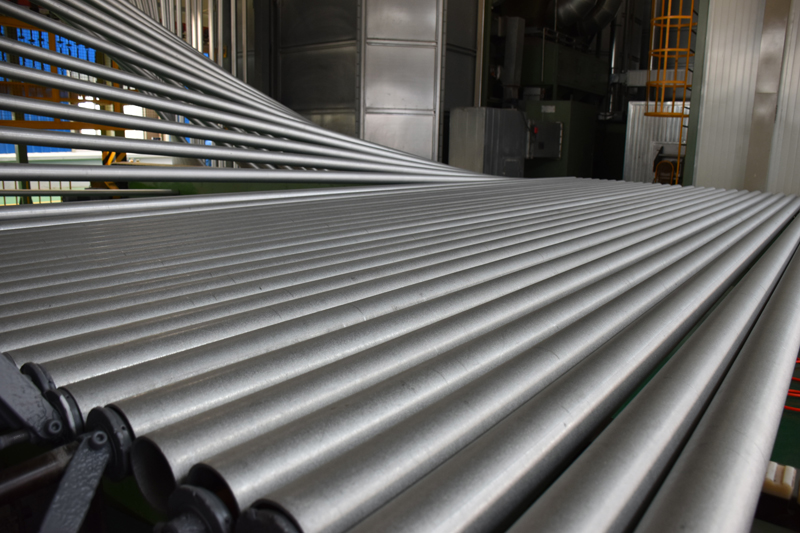

The pre-coated steel pipe is a new type of green pipe developed by Jinzhou Pipe Joint Research Center. It is based on the high-quality hot-dip galvanized steel pipe (or black pipe) produced by our company, and coated with one or more layers of epoxy polyester paint on the surface of the steel pipe by advanced electrostatic spraying process. The product has good mechanical properties and strong corrosion resistance. The annual production capacity of more than 20,000 tons, product quality in line with GB/T 42541 "gas pipeline coated steel pipe" standard requirements, the performance indicators reach the domestic advanced level, can be widely used in urban gas pipeline transportation.

Technical parameters

- Specification:

- DN15-DN150

- Wall thickness:

- 2.6 mm to 6.0 mm

- Length:

- 2.0 m to 6.1 m

- Criteria:

- GB/T 42541

- Material:

- Q235B, 20#, epoxy polyester paint

-

Excellent corrosion resistance

Spray a layer of two-component epoxy polyester paint or a layer of two-component epoxy polyester paint plus a layer of acrylic acid on the substrate. After curing, the coating has good adhesion and uniform coating thickness. The outer wall of the product has double protection effect of coating layer and galvanized layer, excellent anti-corrosion performance, suitable for urban gas pipeline. -

Excellent mechanical properties

With galvanized steel pipe (or black pipe) as the matrix, it has excellent mechanical properties and strong resistance to impact, bending and pressure.