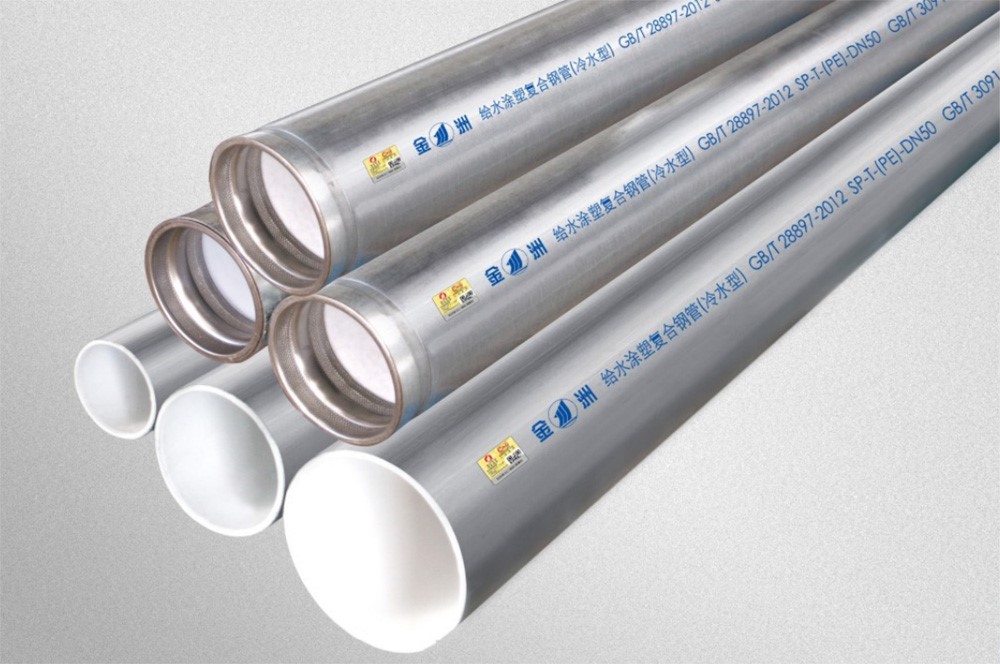

The water-coated composite steel pipe is made of high quality hot-dip galvanized steel pipe made by the company as the matrix, and the polymer material is sucked (sprayed) on the inner wall of the steel pipe by vacuum suction (spray) coating process. The product quality conforms to GB/T28897, CJ/T120 standards, and the health performance conforms to GB/T17219 standards. It is suitable for drinking water and industrial water.

Technical parameters

- Specification:

- DN15-DN200

- Wall thickness:

- 2.6 mm to 6.0 mm

- length :

- 2.8 m to 6 m

- Standard :

- GB/T 28897, CJ/T 120 Objective

- Material:

- Q195, Q215A, Q215B, Q235A, Q235B, Q355, 20#; Plastic: PE

-

Strong corrosion resistance

The conveying fluid is completely isolated from the metal body, only in contact with the coating, which has excellent corrosion resistance and prolongs the service life of the pipeline. -

High mechanical strength

Plastic coated steel pipe and hot dip galvanized steel pipe have the same mechanical strength, impact, bending and pressure has a high tolerance, the use of pressure range of ≤1.6MPa, seamless steel pipe >1.6MPa. -

Excellent hygiene performance

The coating is made of food grade polyethylene or epoxy resin powder, and the sanitary performance is in line with the national standard of drinking water transmission and distribution. -

Small fluid resistance

The inner wall of the plastic coated steel tube is smooth, the friction coefficient is small, the flow rate is fast, the scale is not accumulated, and the fluid resistance is small.

| Serial number | item mu | Sex Can To be o |

| 1 | Coating adhesion | Test with the pull method, ≥30N/10mm |

| 2 | pinhole test | No electric spark breakdown occurs |

| 3 | Bending test (nominal aperture ≤50mm) | The coating does not peel and break |

| 4 | Flattening test (nominal aperture ≥65mm) | The coating does not peel and break |

| 5 | Impact test | The coating does not peel and break |

| 6 | Hygiene performance | Meet the requirements of "Standard for Health and Safety Evaluation of Drinking Water transmission and Distribution Equipment and Protective Materials" (2001) |

Note: When measuring adhesion, if the film breaks, it is considered to have sufficient adhesion.